Surgical procedure technology has made huge strides in the past several years, as new technologies are being developed year-on-year to help with this. Surgeries have increased in safety, accuracy, and success in the digital era due to the new technologies being less invasive compared to older technologies. This is all part of the digital transformation in healthcare.

3D printing technology is used in a lot of industries these days, including creating consumer products, industrial products, and automotive prototypes. It has also revolutionised patient care during surgical procedures, as it offers personalised solutions. The door has now been opened to offer patients greater precision through the creation of customised equipment that can be personal to each patient.

In this article, we will take a closer look at how 3D printing can create personalised surgical solutions and how it can help streamline the surgical process and make it more efficient.

Anatomic models

Surgical planning is now far more effective than ever before with the use of 3D printing, as anatomic models can now be created for a more detailed analysis. These models can be a replica of a patient’s anatomy, which gives the surgeon the most realistic environment to plan the procedure.

Surgeons can now better understand the intricacies of the surgical site, as everyone’s anatomy will be slightly different. These models also help with patient communication, as surgeons can offer a more detailed description of what the patient can expect from the procedure. Before 3D printing, these anatomical models would be more general and not specific to a patient, which could hinder the results of the procedure.

Patient-specific implants

3D printing can create patient-specific implants that perfectly fit the patient’s anatomy without risking them being undersized or oversized. Standard sizes and shapes have previously been the norm for these implants, which isn’t ideal for patients who have specific size requirements. The new level of personalisation ensures a better implant fit, reduces the risk of any complications, and increases the success rate.

In the field of musculoskeletal oncology, 3D printing has made a significant impact. The improvement of 3D printing technology has allowed the creation of customised implants to handle complex reconstructions. This has improved patient outcomes for those who have suffered from a severe musculoskeletal issue.

Surgical guides

Complex procedures have been given a boost with the use of 3D printing, as surgical guides can now be created to assist surgeons. The guides can consist of patient-specific information and anatomical data. This can help surgeons better understand a specific patient’s anatomy, with the hope of increasing the success rate of the surgery.

The precision of the cuts, drilling, and implantation will all improve when surgeons have a surgical guide in place. Other than the success rate, there are other benefits to having surgical guides available to surgeons, such as reduced surgery time.

Quick prototype creation

Before the development of 3D technology, prototypes could take a long time to create. However, 3D printing offers a fast and flexible solution to prototyping and innovation in surgical procedures. Surgeons can refine designs at a much quicker rate, which can allow more surgical tools, devices, and implants to be made.

This quick prototyping has specifically improved facelifts in London. For example, the Guy’s and St Thomas’ Charity awarded a grant to the NHS for the purchase of a new 3D printer that has helped with a wide range of surgical procedures. This has benefited both medical and cosmetic procedures.

Student practice

Medical education has also been positively affected by the use of 3D printing technology. Students who are studying or practicing to become surgeons sometimes don’t have access to advanced technology and equipment, such as cadaveric anatomic models. These types of models are of specific use to medical students, as they can help them with a variety of ventricular septal defects.

The 3D printing technology available can also be used to produce accurate surgical simulations for medical students to better learn the process. Before this technology, the process of learning and understanding the surgical process was far more complicated.

Types of 3D printing technology

It’s worth exploring the different types of 3D printing technology that are available to medical practitioners to streamline the surgical process. The main types of 3D printers include:

- Fused Deposition Modelling (FDM): This uses thermoplastic polymers such as polylactic acid to aid the in-house production of basic proof-of-concept models. This makes up 46% of 3D printing machines.

- Stereolithography (SLA): This 3D printer uses a variety of resins for dental models, surgical guides, and orthodontic devices.

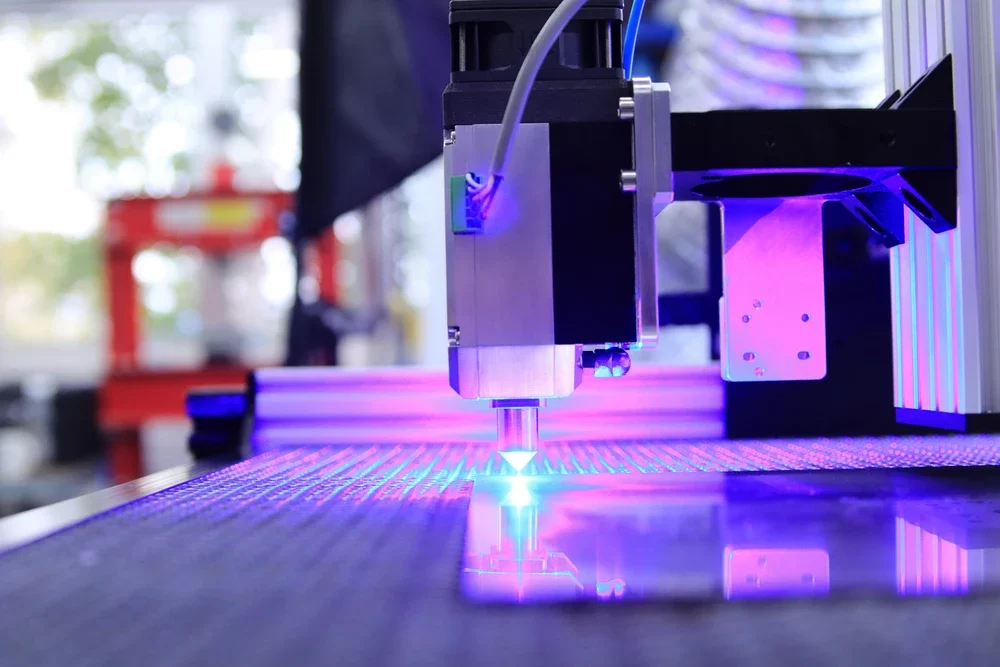

- Selective Laser Sintering (SLS): Hospitals can use this to set up metal crowns, copings and bridges. It can also be used for resin partial denture framework.

- Polyjet Printing: A variety of photopolymers help set up the manufacturing of craniomaxillofacial implants and sophisticated anatomical models.

- Bioprinter: Cell-loaded gels and inks based on collagen are used to focus on the creation of cell-laden scaffolds for hard and soft tissue printing.

One of the newer 3D technologies is Schiner 3D Repro GmbH’s Digital Anatomy Printer, which can help simulate anatomies and pathologies with ultra-realistic 3D models. This reduces the need for human and animal cadavers, which results in higher repeatability.

The future of 3D printing in surgery

As technology advances, we should see further improvements in the use of 3D printing in surgical procedures. These advancements should enhance the precision, speed, and accuracy of 3D-printed medical devices, through methods such as:

- Laser-Reinforced Bioprinting: The combination of lasers and bioprinting could lead to a stronger creation of more stable tissues and organs. The laser light would likely act as an external support and eliminate the current limitation found with bioprinting.

- Multi-Material Printing: Printing multiple materials simultaneously is something we have yet to see with one 3D printing device. Being able to do this could allow for the fabrication of more complex devices.

- Scalable Manufacturing: Larger quantities of customer medical devices can be produced if there are more innovations in scalable manufacturing. This will also reduce costs and increase accessibility.

The end goal of 3D printing technology is to successfully print organs using a patient’s cell to use in transplants. However, 3D printing such a complex thing remains difficult and it will need a lot more research and development beforehand.